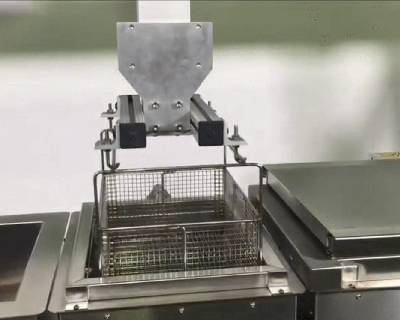

The fitting and assembly section handles special processes, final assembly and packaging of all products before they can be shipped to our respective clients. All secondary operations like deburring, tapping, drilling, polishing, and ultrasonic cleaning are conducted here.

We also have a cell for Precision TIG Welding for Stainless Steel and Stellite Welding, Assembly area, Tool room and well-equipped staff to work on Secondary Operations like Welding, Ultrasonic Cleaning, Lapping, etc. We specialize in Dye Penetrant testing, Ultrasonic Crack detection test, Magnetic Particle and Radiography testing.

Gemsons has a Tool Room for the manufacturing of jigs, fixtures, dies, special gauges and assemblies, etc. The Tool Room is equipped with skilled manpower along with conventional machines having Digital Read-Outs (DRO). Our tool room facilities include Jig-Boring, Surface Grinding, Milling machines, Lathes, Wire EDM, Cylindrical Grinding, etc.

We manufacture product-specific jigs, fixtures, and assembly aides to ensure perfection in all the assembled components. Our Tool Room is equipped with the necessary facilities, machinery, and skilled manpower to support our CNC machine shop to the fullest.

TIG Welding for Stainless Steel and Stellite Welding

Super Finishing Processes like Surface Lapping

Laser marking and 2D barcoding

Surface and Cylindrical grinding

Deburring and Assembly

Secondary Inspection