Table Of Content

- Definition and Types of Machined Shafts:

- Materials and Size Considerations:

- Design Aspects:

- Application and Advantages:

- Advantages of machined shafts include:

- Disadvantages:

- Why choose Gemsons Precision Engineering Pvt Ltd

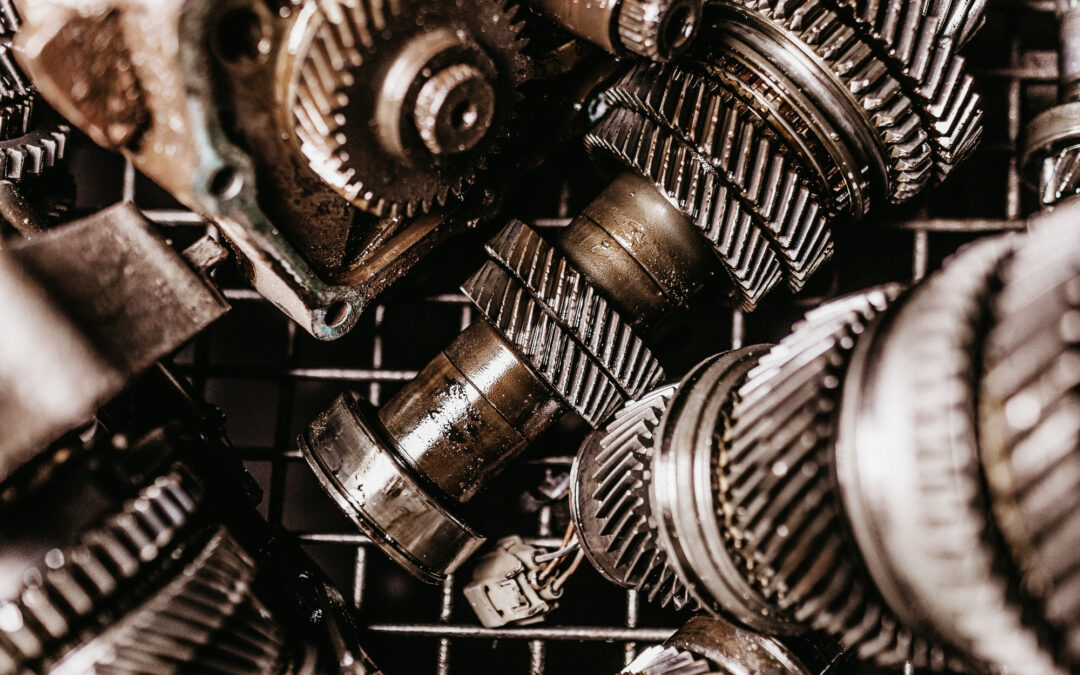

Machined shafts are crucial components in various mechanical systems, providing rotational motion and transmitting power. They play a vital role in countless applications, from automobiles to industrial machinery. Understanding the definition, types, materials, size considerations, design aspects, and the pros and cons of machined shafts is essential for engineers and manufacturers. In this blog, we will explore these aspects in detail, shedding light on the versatility and significance of machined shafts in the realm of precision engineering.

Definition and Types of Machined Shafts:

Machined shafts, also known as mechanical shafts, are cylindrical components with a uniform diameter and length. They are typically made from metal or alloy materials and are precisely machined to meet specific dimensional tolerances. These shafts come in various types based on their design and applications.

- Solid Shafts: These are solid, continuous shafts with a consistent diameter throughout their length. They are commonly used in applications where high torque and bending stiffness are required.

- Stepped Shafts: Stepped shafts have varying diameters along their length. They are used to transmit power from different-sized components, ensuring a proper fit and optimal performance.

- Splined Shafts: Splined shafts have axial splines or grooves that mate with corresponding components, such as gears or couplings. They provide torque transfer while allowing relative axial movement.

- Hollow Shafts: Hollow shafts have a central void, reducing weight and providing space for the passage of fluid, wiring, or other components. They are commonly used in applications where weight reduction is crucial.

Materials and Size Considerations:

Machined shafts are typically made from a range of materials, selected based on their specific application requirements. Common materials include steel, stainless steel, alloy steel, aluminum, and titanium. The choice of material depends on factors such as strength, corrosion resistance, temperature resistance, and cost.

Size considerations for machined shafts involve determining the appropriate diameter, length, and tolerances. Factors such as torque, load, rotational speed, and critical dimensions of mating components influence the sizing process. Proper sizing ensures optimal functionality, minimizes stress, and maximizes the lifespan of the shaft.

Design Aspects:

The design of machined shafts involves careful consideration of various factors to ensure optimal performance and longevity. Here are some essential design aspects:

- Shaft Diameter and Length: Determined by the application requirements, including torque, load, and available space.

- Keyways and Keyseats: Keyways are slots on shafts that accommodate keys, ensuring a secure fit with components like gears or pulleys.

- Surface Finish: Machined shafts require a smooth surface finish to reduce friction and prevent premature wear.

- Tolerances: Machined shafts must be manufactured with precise tolerances to ensure proper fit and alignment with mating components.

Application and Advantages:

Machined shafts find application in numerous industries, including automotive, aerospace, machinery, and robotics. Some common applications include:

- Automotive Industry: Machined shafts are used in engines, transmissions, drivetrain systems, and steering mechanisms.

- Industrial Machinery: They are employed in pumps, compressors, conveyors, and power transmission systems.

- Robotics: Machined shafts play a critical role in robotic arms and joint mechanisms.

Advantages of machined shafts include:

- Precision and Reliability: Machined shafts are manufactured to precise tolerances, ensuring accurate performance and reliable operation.

- High Strength and Durability: Machined shafts made from sturdy materials exhibit excellent strength, resisting heavy loads and wear.

- Versatility: Machined shafts come in various types and sizes, catering to a wide range of applications.

Disadvantages:

While machined shafts offer numerous advantages, they also have some limitations:

- Cost: High-quality machined shafts can be expensive, especially when made from specialized materials.

- Manufacturing Complexity: Producing machined shafts with intricate designs and features can be challenging and time-consuming.

Applications Of Machined Shafts In The Aerospace Industry

Why choose Gemsons Precision Engineering Pvt Ltd

Gemsons Precision Engineering Pvt Ltd is a leading provider of machined shafts and precision engineering solutions. When it comes to choosing a reliable partner for your machined shaft needs, there are several reasons why Gemsons Precision Engineering stands out:

- Expertise and Experience: Gemsons Precision Engineering boasts a team of highly skilled engineers and technicians who have extensive expertise in the field of precision engineering. With years of experience, they have successfully delivered high-quality machined shafts for various industries and applications. Their in-depth knowledge allows them to understand customer requirements and provide tailored solutions.

- State-of-the-Art Infrastructure: Gemsons Precision Engineering is equipped with advanced infrastructure and cutting-edge machining facilities. They leverage the latest technologies and equipment to ensure precise manufacturing of machined shafts. Their state-of-the-art CNC machines, along with rigorous quality control measures, guarantee exceptional accuracy, surface finish, and dimensional tolerances.

- Customization and Flexibility: Gemsons Precision Engineering understands that each project has unique requirements. They offer a high degree of customization to meet specific customer needs. Whether it’s a particular shaft design, material preference, or specialized surface treatment, they have the capability to deliver tailor-made solutions. Their flexible approach ensures that customers receive machined shafts that perfectly match their application requirements.

- Quality Assurance: Maintaining the highest standards of quality is a top priority for Gemsons Precision Engineering. They adhere to stringent quality control procedures throughout the manufacturing process. From material selection to final inspection, every step is closely monitored to ensure that machined shafts meet the required specifications and performance criteria. Their commitment to quality is reflected in their ISO 9001 certification.

- Timely Delivery: Gemsons Precision Engineering understands the importance of timely delivery in today’s fast-paced industries. They have streamlined their production processes to ensure efficient turnaround times without compromising on quality. Their dedicated team works closely with customers to meet project deadlines and deliver machined shafts within the agreed-upon timeframe.

- Customer Satisfaction: Gemsons Precision Engineering takes pride in building strong, long-term relationships with its customers. They prioritize customer satisfaction and strive to exceed expectations at every stage of the engagement. Their responsive and dedicated customer support team is always available to address queries, provide technical assistance, and offer post-sales support.

In conclusion, choosing Gemsons Precision Engineering Pvt Ltd as your partner for machined shafts ensures access to a team of experts, state-of-the-art infrastructure, customization options, stringent quality control, timely delivery, and exceptional customer satisfaction. Their commitment to precision engineering and dedication to meeting customer requirements make them a reliable choice for all your machined shaft needs.

Recent Comments