Table Of Content

- What are Machined Shafts?

- Types of Machined Shafts

- Manufacturing Processes

- Key Considerations in Machined Shaft Design

- Applications of Machined Shafts:

- Gemsons Precision Engineering Pvt Ltd: Your Trusted Partner for Machined Shafts

- Choose Gemsons Precision Engineering Pvt Ltd for your Machined Shaft Needs

- Frequently Asked Questions (FAQs)

- Related Topics:

Gemsons Precision Engineering Pvt Ltd is proud to present a comprehensive guide on machined shafts. Machined shafts are vital components used in various industries and applications, ranging from automotive and aerospace to manufacturing and construction. This guide will provide you with a detailed understanding of machined shafts, their types, manufacturing processes, and applications. Let’s dive into the world of machined shafts and explore their significance in engineering.

What are Machined Shafts?

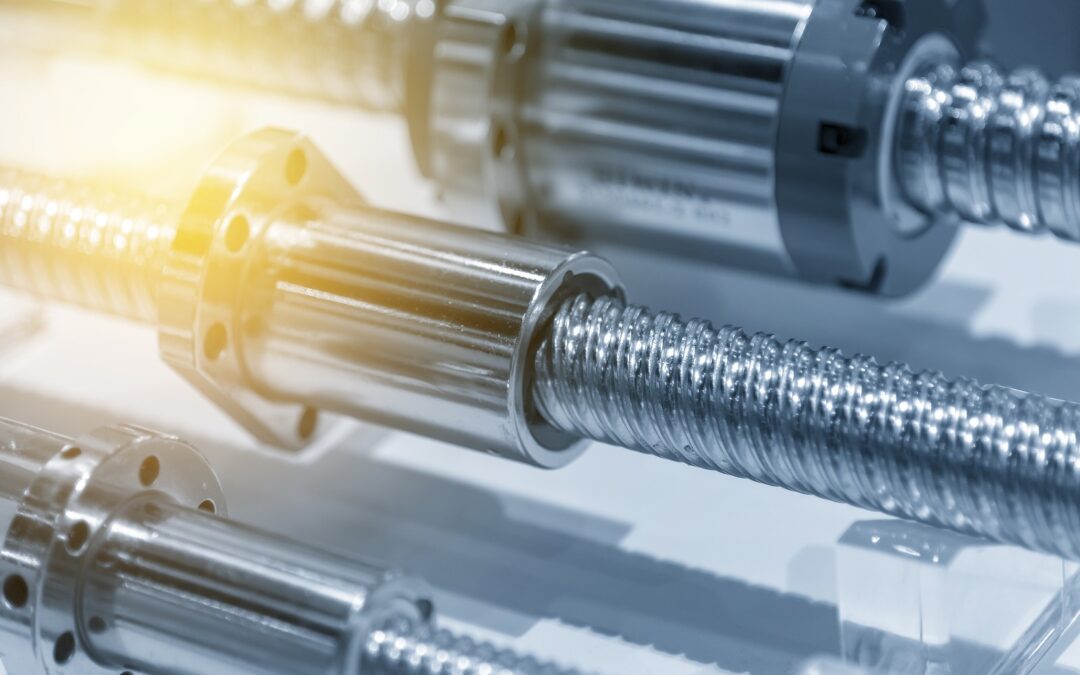

Machined shafts are cylindrical mechanical components that transmit rotational motion and power between different machine elements. These shafts are typically made of metals such as steel, stainless steel, aluminum, or titanium, depending on the application requirements. Machined shafts play a crucial role in transferring torque and rotational force within machinery, ensuring smooth operation and efficiency.

Types of Machined Shafts

There are several types of machined shafts, each designed to fulfill specific requirements. Some common types include:

a) Solid Shafts: These shafts are uniform in diameter throughout their length and are used when a high level of strength and rigidity is needed.

b) Hollow Shafts: Hollow shafts have a central void, offering reduced weight without compromising strength. They are commonly used in applications where weight reduction is critical, such as aerospace.

c) Stepped Shafts: Stepped shafts have multiple sections with different diameters. They are used when different components require varying shaft sizes or for coupling with different parts.

d) Splined Shafts: Splined shafts have grooves or splines along their length, allowing for the connection of other components, such as gears or couplings.

e) Tapered Shafts: Tapered shafts have a gradual reduction in diameter along their length. They are commonly used in applications where components need to be mounted securely, such as automotive wheel hubs.

Manufacturing Processes

Machined shafts are manufactured using various processes to achieve the desired dimensions, surface finish, and precision. The key manufacturing processes include:

a) Turning: Turning is the process of rotating the shaft while removing excess material using cutting tools. This process helps achieve the required diameter and surface finish.

b) Grinding: Grinding is used to refine the surface finish of machined shafts and provide high precision. It involves using abrasive wheels to remove material and attain the desired tolerance and surface quality.

c) Milling: Milling is the process of removing material using rotating cutters to create features such as keyways, splines, or flats on the shaft’s surface.

d) Heat Treatment: Heat treatment processes like quenching and tempering are used to enhance the mechanical properties of machined shafts, such as hardness, strength, and toughness.

Key Considerations in Machined Shaft Design

Designing machined shafts requires careful consideration of several factors to ensure optimal performance. Some essential considerations include:

a) Load and Torque: Determining the expected load and torque the shaft will experience is crucial for selecting the appropriate material and diameter to prevent failures.

b) Shaft Material: Choosing the right material based on factors such as strength, corrosion resistance, and temperature resistance is vital to ensure the shaft’s longevity.

c) Shaft Length and Diameter: Determining the appropriate shaft length and diameter based on the application’s requirements helps prevent deflection and excessive vibrations.

d) Surface Finish: Achieving the required surface finish is essential to minimize friction, wear, and stress concentration, thereby increasing the shaft’s lifespan.

Applications of Machined Shafts:

Machined shafts find applications across various industries and machinery. Some common applications include:

a) Automotive Industry: Machined shafts are used in engines, transmissions, steering systems, and drivetrain components.

b) Aerospace Industry: They are utilized in aircraft engines, landing gear systems, and control surfaces.

c) Industrial Machinery: Machined shafts play a crucial role in pumps, compressors, conveyors, and power transmission equipment.

d) Construction and Mining: They are used in heavy machinery, excavators, cranes, and drilling equipment.

Gemsons Precision Engineering Pvt Ltd: Your Trusted Partner for Machined Shafts

At Gemsons Precision Engineering Pvt Ltd, we take pride in our expertise in manufacturing high-quality machined shafts. With years of experience and a commitment to precision engineering, we have become a trusted partner for numerous industries worldwide. Here’s why you should choose Gemsons for all your machined shaft needs:

- Quality Assurance:

At Gemsons, quality is our top priority. We adhere to stringent quality control measures throughout the manufacturing process to ensure that our machined shafts meet or exceed industry standards. Our skilled engineers and technicians meticulously inspect every shaft to guarantee dimensional accuracy, surface finish, and mechanical properties. With Gemsons, you can expect nothing less than excellence.

- Customization:

We understand that each application has unique requirements. That’s why we offer customizable solutions for machined shafts. Our team of engineers works closely with clients to understand their specific needs and design shafts that precisely match their requirements. Whether it’s a particular material, size, or surface finish, we have the capabilities to deliver tailor-made machined shafts that meet your expectations.

- State-of-the-Art Manufacturing Facilities:

Gemsons Precision Engineering Pvt Ltd boasts state-of-the-art manufacturing facilities equipped with advanced machinery and technology. Our CNC turning, milling, and grinding machines enable us to achieve exceptional precision and tight tolerances. With a focus on continuous improvement, we regularly invest in upgrading our equipment to stay at the forefront of the industry and deliver superior machined shafts.

- Material Expertise:

Choosing the right material is crucial for the performance and longevity of machined shafts. At Gemsons, we have extensive material expertise and work with a wide range of metals, including stainless steel, carbon steel, alloy steel, aluminum, and titanium. Our team can guide you in selecting the most suitable material based on your application requirements, ensuring optimal strength, durability, and corrosion resistance.

- Timely Delivery:

We understand the importance of timely delivery in today’s fast-paced industries. At Gemsons, we have efficient production planning and scheduling processes in place to ensure on-time delivery of machined shafts. Our streamlined operations, coupled with our commitment to meeting deadlines, make us a reliable partner you can count on.

- Competitive Pricing:

Gemsons Precision Engineering Pvt Ltd offers competitive pricing without compromising on quality. We strive to provide cost-effective solutions for machined shafts, enabling you to achieve the desired performance within your budget. Our transparent pricing structure ensures that you receive fair and competitive rates for our products and services.

- Commitment to Customer Satisfaction:

At Gemsons, we value our customers and prioritize their satisfaction above all else. We believe in building long-term partnerships based on trust, reliability, and exceptional service. Our dedicated customer support team is always ready to assist you with any queries, provide technical guidance, and address your concerns promptly.

Choose Gemsons Precision Engineering Pvt Ltd for your Machined Shaft Needs

When it comes to machined shafts, Gemsons Precision Engineering Pvt Ltd stands out as a reliable and experienced manufacturer. With our commitment to quality, customization capabilities, advanced manufacturing facilities, and customer-centric approach, we are the ideal partner for your machined shaft requirements.

Contact us today to discuss your specific needs and experience the excellence of Gemsons machined shafts. Let us help you achieve optimal performance, reliability, and efficiency in your machinery. Trust Gemsons for precision engineering at its finest.

Frequently Asked Questions (FAQs)

Can Gemsons Precision Engineering Pvt Ltd provide machined shafts with custom surface finishes?

Yes, at Gemsons, we have the capability to provide machined shafts with a wide range of surface finishes. We can achieve finishes such as smooth, polished, blasted, or coated, based on your specific needs and application requirements.

What is the typical lead time for manufacturing machined shafts?

The lead time for manufacturing machined shafts can vary depending on factors such as quantity, complexity, and customization requirements. At Gemsons, we strive to provide an efficient turnaround time and work closely with our clients to meet their delivery timelines.

Are there any restrictions on the length or diameter of the machined shafts Gemsons can manufacture?

Gemsons Precision Engineering Pvt Ltd has the capability to manufacture machined shafts of varying lengths and diameters. We work with our clients to understand their specific requirements and design shafts accordingly. However, it is always recommended to consult with our engineers regarding the maximum dimensions that can be achieved based on material properties and machining capabilities.

Can Gemsons provide machined shafts with specialized coatings for corrosion resistance?

Yes, we can provide machined shafts with specialized coatings for enhanced corrosion resistance. Coatings such as chrome plating, nickel plating, or various types of coatings can be applied to protect the shafts from corrosive environments and extend their lifespan.

Does Gemsons offer post-machining heat treatment services for machined shafts?

Yes, we provide post-machining heat treatment services for machined shafts. Heat treatment processes like quenching and tempering can be applied to improve the mechanical properties of the shafts, such as hardness and strength, based on your specific requirements.

Can Gemsons assist with the design and engineering of machined shafts?

Absolutely! Our team of experienced engineers can provide design and engineering support for your machined shafts. We can collaborate with you to optimize the design, select the appropriate materials, and ensure that the shafts meet your performance and application needs.

Does Gemsons Precision Engineering Pvt Ltd offer prototype manufacturing for machined shafts?

Yes, we offer prototype manufacturing services for machined shafts. Prototyping allows you to test and validate the design before proceeding with full-scale production. Our team can work closely with you to develop prototypes that meet your specifications and help you make informed decisions.

Can Gemsons accommodate small-volume or large-volume orders for machined shafts?

Yes, Gemsons Precision Engineering Pvt Ltd has the flexibility to accommodate both small-volume and large-volume orders for machined shafts. We understand the varying needs of our clients and have the capacity to scale our production accordingly.

Are Gemsons machined shafts compliant with industry standards and certifications?

Yes, our machined shafts adhere to industry standards and certifications. We maintain strict quality control processes and ensure that our products meet the required specifications and certifications, such as ISO 9001:2015.

If you have any additional questions or specific inquiries regarding machined shafts, feel free to contact Gemsons Precision Engineering Pvt Ltd. Our knowledgeable team is ready to assist you and provide tailored solutions to meet your machining needs.

Related Topics:

Machined Shafts: An Overview Of Custom Machined Shafts, The Shaft Machining Process, And Machine Shaft Examples

Recent Comments