Precision turning plays a significant role in the manufacturing industry, particularly within areas that would respond to the slightest variation in performance and functionality, as it directly influences the operation and functionality of machinery. Precision turned components are useful within automotive systems and industrial machinery. This manufacturing process aims to ensure that turned components are of precise dimensions and have uniform quality, which is crucial when it comes to fitting perfectly without fail.

Understanding Precision Turning at Its Core

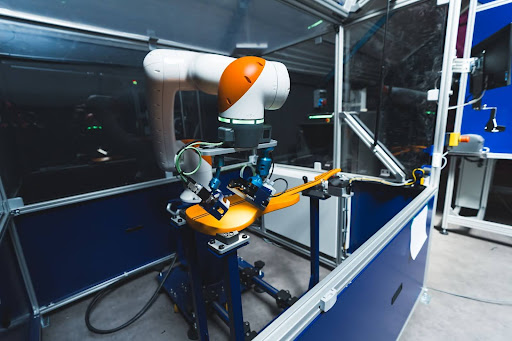

Precision turning is a machining operation wherein the material is removed from the rotational workpiece through the aid of sophisticated lathe tools. However, it is not merely the equipment used in precision turning, but rather the level of control exercised in terms of speed, feed rate, tools, and methods of measurement. Turning centers have been developed in such a way as to ensure micron accuracy despite the difficulties encountered in terms of geometries and hardness of materials.

Equally critical is process stability. Doing things right in controlled environments with calibrated equipment and competent operators results in reduced variation. This also ensures that the first part produced is of similar dimensions to the thousandth part produced.

How Tight Tolerances Are Maintained

The achievement of high accuracy involves more than a single process, it involves planning, technology, and hard work. Processors use systematic work processes in order to reduce the possibility of mistakes even before they happen.

Key practices are:

- Tool selection and maintenance: Sharpened tools suited to the particular job reduce vibration and dimensional change.

- Material control: Homogeneous material characteristics make machining more predictable.

- In-process inspection: Defects are prevented from moving ahead during the time of production.

- Temperature control: Expansion is caused by heat. This is why equipment and manufacturing floors are carefully regulated.

These steps will help guarantee that all qualities, ranging from diameter through depth of threading, meet specifications.

Measurement Systems That Support Accuracy

Precision turning will always be somewhat dependent on accurate measurement and verification systems. Quality producers will deploy advanced inspection tools, including digital micrometers, CMMs, and optical measurement systems, to validate dimensions at every stage. These tools will detect even the slightest deviations early in the process, minimizing scrap and rework. Consistent calibration of measuring instruments is key to instilling confidence in production data. This is particularly true when parts are subject to severe industry or customer-defined specifications.

Consistency Across Batches and Volumes

In high-demand sectors, consistency is as critical a factor as accuracy. When a company increases its manufacturing scale, consistency in products is expected. This is where precisian turned components show their true value. These components ensure consistency, no matter how many are manufactured at one time.

Modern turning operations are increasingly using automation and real-time control to improve cycle time efficiency with the ability to maintain dimension integrity. Dimension integrity refers to the overall dimensional strength or integrity of the work.

The Role of Process Expertise

However, precision will not be achieved simply through the use of technology. Experienced machinists or process engineers are required who read drawings, choose appropriate variables, and tweak process details based on practical results. This enables them to overcome typical problems, like tool wear variation or surface finish, to generate desired functional as well as esthetic results.

Where Accuracy Meets Responsibility

From our perspective at Gemsons, long-term precision comes from respecting the process as much as the product. In manufacturing, precision turned components require appropriate machining as well as ongoing improvement. Today in the manufacturing world, it is possible to be accurate as well as efficient in areas such as CNC turning, tolerancing, surface finish, automobile components, and large-scale manufacturing.