Accuracy in manufacturing nowadays is simply taken for granted, and even more, it is an essential requirement. With component designs getting more complex and tolerances to components getting tighter, manufacturers will always find advanced non-traditional methods that are more efficient and allow them to get consistent results. In this evolution, wire EDM machining processes have come to be one of the most essential tools that can make the production of incredibly complex parts possible, which would have been difficult or impossible to do with conventional cutting tools. This process is capable of offering a very reliable solution for industries that will not compromise on precision, be it hard metals or delicate geometries.

How the Process Actually Works

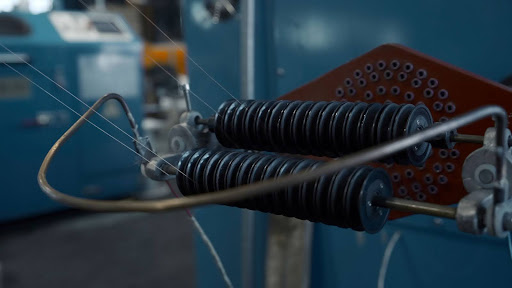

Wire EDM is a non-contact machining process that employs electrical discharges to cut parts made of conductive materials. An electrode is the cutting tool, but instead of a solid cutting tool, it is a thin wire that is constantly fed, normally made of brass or copper, coated, hence the electrode is the wire. The wire never touches the workpiece. In this case, the controlled electrical sparks are used to erode the material along the programmed path.

The wire and workpiece are immersed in deionized water, which functions as the dielectric fluid. This fluid cools the cutting zone, washes away eroded particles, and keeps the spark stable. Because no physical force is applied when cutting, extremely thin or fragile components can be produced with very high dimensional accuracy.

This method is quite good for materials that have been very hardened through heat treatment, as the cutting performance is not affected by the material’s hardness.

Key Stages in the Machining Cycle

Although it is a high-tech process, the process itself steps through a clear, understandable sequence of events:

- Design input and programming: CAD/CAM software defines the cutting path with high accuracy.

- Wire threading: Fine wire, usually about 0.1 mm in diameter, is automatically threaded through the hole.

- Controlled spark erosion: Electrically charged impulses cut through the material directly in the programmed contour.

- Multiple skim cuts: Additional passes increase surface finish quality and correct dimensions.

The process is repeatable due to the precise control of the wire and of the spark, allowing for prototype and batch production.

Why Manufacturers Depend on This Technology

The main advantage of wire EDM is precision without creating material stress. Parts do not lose their structural integrity and dimensional stability because the forces from the mechanical cutting are absent.

Besides these advantages, there are:

- Exceptional accuracy: It is possible to have tight tolerances and sharp internal corners.

- Superior surface finish: Only a few secondary finishing operations are needed.

- Material versatility: In addition to hardened steels, carbides, and titanium, the process can also be used on exotic alloys.

- Design freedom: Complex profiles, narrow slots, and fine features can be produced reliably.

To the point manufacturers that value quality and consistency, these benefits mean better performance and less rework.

Where the Technology Makes the Greatest Impact

This technique is widely used in all kinds of industries, especially where the applications require the highest precision and reliability. Toolrooms depend on it for making punches, dies, and molds that are very detailed. Besides, in aerospace and medical manufacturing sectors, the technology makes it possible to produce components that have complex internal geometries and are governed by very strict tolerances.

Production-level wire EDM machining is typically used to make:

- Extrusion and injection mold components

- Precision gears and mechanical parts

- Fixtures and gauges requiring high dimensional accuracy

- Components made from heat-treated or hardened materials

Its great flexibility is what makes it more of a long-term solution rather than just a niche process.

Design Considerations for Optimal Results

In order to take full advantage of this machining method, parts should be designed with the process in mind. Uniform material thickness, sufficient start holes, and reasonable tolerance expectations are some of the factors that facilitate efficient production. Although the process performs with precision, thoughtful design will shorten the cycle time and increase the overall consistency level.

Operationally, surface finish and accuracy are greatly influenced by the precise handling of parameters such as wire tension, spark frequency, and flushing pressure. Hence, achieving results that can be repeated depends on the skills of the operators and the condition of the machines.

Maintaining Accuracy Through Process Control

Such a situation is the case where high precision machining can depend in a very good manner on the level of process control. In the case of wire EDM operations, it is necessary that all of the factors, such as wire tension, dielectric fluid quality, and spark parameters, remain unchanged during the whole machining cycle. Sometimes, slight changes are enough to alter the surface finish or the dimensional accuracy of the parts, especially if the ones with very small tolerances are involved. By closely monitoring these parameters and following standardized operating practices, manufacturers can ensure repeatable quality across batches. This level of control is extremely necessary for the parts destined to be incorporated into the assemblies, where performance and reliability are dependent on the machining precision.

Supporting Complex Manufacturing Requirements

As product lifecycles become shorter and personalization goes higher, manufacturers require extremely flexible processes. Wire EDM is great from this perspective because it can keep up with rapid design changes without the need for new tools, therefore, perfectly embodying the needs of changing requirements and low-to-medium volume production.

Besides, it can be perfectly combined with other advanced manufacturing processes, thus making it possible for enterprises to develop total solutions centered on precision machining, tooling, and component development.

A Technology That Continues to Shape Modern Manufacturing

In such a world where tolerances become tighter and materials more sophisticated, wire EDM machining is still among the key elements of precision manufacturing. Throughout the various industries, it has been proven to be an essential tool due to its capacity to cope with complex designs, hardened materials, and stringent quality standards. Coupled with profound knowledge of the process and a strong commitment to engineering excellence, this technology paves the way for manufacturers to confidently take the journey from initial idea to finished product.

At Gemsons, this level of knowledge is just one part of the overall commitment to precision-driven manufacturing solutions. In fact, when the process is combined with the capabilities of CNC machining, precision engineering, tool and die manufacturing, aerospace components, and automotive components, the process supports consistent quality, technical reliability, and long-term manufacturing value; exactly what modern industries require.

Recent Comments