Precision machining parts are essential to many industries, including aerospace, automotive, medical, and electronics. They are used in various applications requiring high accuracy and performance consistency. Precision machining parts are manufactured using advanced technology and equipment tob meet the required specifications. This article will explore the key components of precision machining parts.

Materials Used for Precision Machining Parts:

Depending on the application requirements, precision machining parts can be made from various materials. Common materials include aluminum, stainless steel, brass, copper, titanium, plastics, and composites. The material chosen must have the required strength and durability and withstand high temperatures or corrosive environments. The selection also depends on factors such as weight reduction or thermal conductivity.

- Design and Engineering:

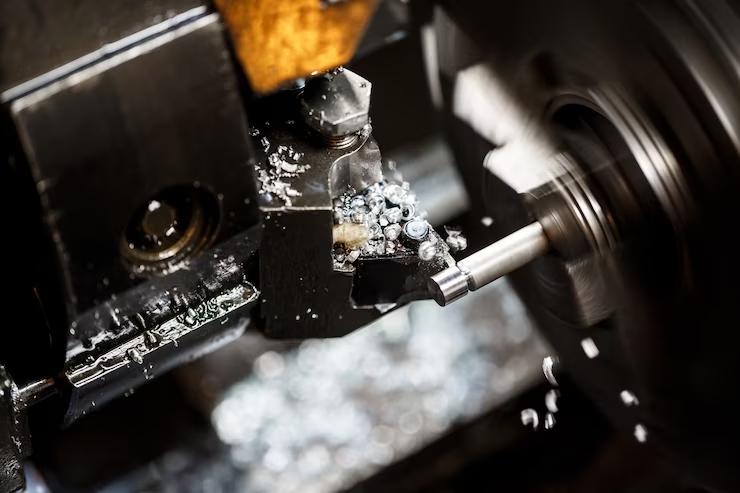

Precision machining parts require careful design and engineering to meet the required specifications. The design process includes creating a 3D model using computer-aided design (CAD) software that is then used to create a prototype using computer-aided manufacturing (CAM) software. Engineering ensures the part is designed for optimal performance while considering factors such as stress distribution analysis and material selection. - CNC Machining:

Computer Numerical Control (CNC) machining is used to manufacture precision machining parts with high accuracy and consistency. CNC machines use programmed instructions to control cutting tools that shape the raw material into the desired shape or form. CNC machines can produce high-precision complex shapes by controlling multiple axes simultaneously. - Grinding:

Grinding is a process used to refine the surfaces or shapes of precision machining parts after machining those using CNC machines. This process helps achieve tighter tolerances than conventional milling or turning processes. Grinding can also improve surface finish quality by removing roughness from previous processes. - Heat Treatment:

Heat treatment is a process used to modify the properties of materials used for precision machining parts through heating or cooling under controlled conditions. Heat treatment can improve mechanical properties such as hardness or ductility while reducing residual stresses caused during manufacturing processes. - Quality Control:

Quality control is essential in precision machining part manufacturing to ensure that each part meets customer requirements and industry standards. Quality control includes inspection of dimensions, surface finish quality, and material properties testing such as hardness or tensile strength.

Benefits of Precision Machining Parts:

Precision machining offers several benefits over traditional manufacturing methods:

- Accuracy: Precision machining produces highly accurate parts with tight tolerances.

- Consistency: Because precision machining uses computer-controlled machines, it produces consistent results every time.

- Speed: Precision machining can produce complex shapes quickly and efficiently without sacrificing accuracy.

- Versatility: Precision machining can produce various shapes and sizes from various materials.

Precision machining parts play a significant role in many industries where accuracy and consistency are crucial for optimal performance. The key components in manufacturing these parts include material selection based on application requirements; design engineering using CAD/CAM software; CNC Machining for accurate shaping; grinding for refining surfaces; heat treatment for modifying material properties; quality control inspections at every stage of production.

Understanding these key components helps manufacturers produce high-quality, precision-machined parts that meet customer expectations while adhering to industry standards. With advancements in technology continually being made in this field, expect even better results from this industry soon!

Recent Comments