Manufacturing today depends on accuracy, consistency, and the ability to handle complex designs with ease. Whether in aerospace, automotive, medical technology, or electronics, industries rely on machining processes that deliver flawless components repeatedly. Two key techniques stand out: CNC turning and CNC milling, methods that seem alike at first glance, yet do separate jobs when it comes to fine detail work. For firms using precision turned components, knowing what sets them apart leads to better decisions, better designs, and better results.

CNC Turning: Mastering Symmetry and Speed

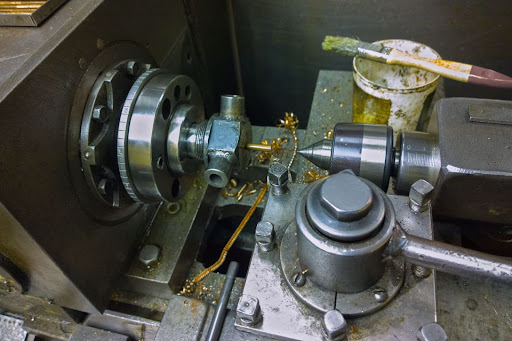

CNC turning works well for creating cylindrical and rotational parts. With this approach, the material spins fast while a fixed blade cuts into it. Because of this design, shaping parts becomes quick and smooth.

- Shafts

- Bushings

- Pins

- Threaded parts

- Round housings

CNC lathes cut as the part spins, so they keep diameters super even with a clean surface. That’s why you’ll find them making aerospace fasteners, automotive steering components, hydraulic parts, and medical implants; no surprises in shape or texture.

At places like Gemsons Precision Engineering, advanced machines run multi-axis lathes equipped with live tools, so tasks such as drilling or tapping get done without switching setups. Because of this, parts move faster from stage to stage while minimizing errors; consistency improves noticeably, especially when cranking out lots of pieces or making vital parts where precision matters big-time.

CNC Milling: Shaping Complex Geometries with Confidence

CNC milling operates another way. Rather than spinning the part, it spins the cutter as it travels over a stationary piece. That method fits well when shaping complex surfaces, pockets, grooves, slots, or intricate contours.

CNC milling excels at machining:

- Complex housings

- Brackets and plates

- Engine blocks

- Cooling plates

- Custom prototypes

Since the tool reaches the material from different sides, like in 4-axis or 5-axis modes, it’s great for complex parts used in power systems, military gear, healthcare tools, or factory automation.

Gemsons uses top-tier milling tools to quickly shape aluminum, stainless steel, titanium, Inconel, or tough plastics. The strength of their gear and the expertise from workers, along with smart software, help them ensure exact cuts every time.

Key Distinctions Between CNC Turning and CNC Milling

While both turning and milling contribute to precision engineering, their core differences define when each should be used.

Motion and Cutting Method

- Turning: Workpiece rotates, and the tool is fixed.

- Milling: Tool rotates, and the workpiece is fixed.

Ideal Part Geometry

- Turning: Cylindrical or round components.

- Milling: Flat, angled, or multi-surface components.

Typical Output

- Turning: Smooth finishes, tight concentricity.

- Milling: Detailed pockets, slots, contours, and 3D shapes.

Speed and Efficiency

- Turning: Faster for symmetrical parts.

- Milling: More time-intensive but highly versatile.

When Both Turning and Milling Work Together

Many components require both processes. A part may need turning for its outer diameter and milling for slots or drilled features. This is where hybrid machines and combined workflows shine.

By mid-2025, high-precision engineering companies will use machines that handle spinning and shaping, all in a single flow. Such setups cut down on delays because tasks link together without pause

- Setup time

- Human intervention

- Tool change delays

- Overall machining cost

When sectors need complex, tailor-made parts, this combined method ensures rock-solid reliability while speeding up delivery.

Material Considerations in Turning and Milling

Different materials react in their own way when cut or shaped. Knowing how a method works with certain materials lets makers keep things precise while avoiding damage to tools.

CNC Turning Works Best For:

- Stainless steel

- Brass

- Aluminum

- Titanium

- Engineering plastics

CNC Milling Excels With:

- Aluminum alloys

- High-strength steels

- Inconel

- Copper

- Composite materials

Firms such as Gemsons rely on smart coatings and durable cutters while applying sharp techniques, helping machines run smoothly despite grinding tough metals used in aerospace or energy sectors.

How Precision Improves With Technology

As demand grows for miniaturized and high-performance parts, both CNC turning and milling continue to evolve.

Key Advancements Include:

- AI-driven toolpath optimization

- Automated in-process inspection

- IoT-enabled machine monitoring

- Digital twin simulations

- High-speed spindles

- Thermal compensation systems

These upgrades cut waste and speed up production while improving precision, key for sectors where even a tiny fraction counts.

Some makers specialize on precision turned components with super-tight specs, down to just a few microns. Hitting those numbers takes top-tier machines, experienced engineers, or strict checks like CMM scans along with live measuring tools.

Practical Guide: Choosing Between Turning and Milling

When deciding which method suits your component, consider:

Use CNC Turning If:

- The part is round or tubular

- You need consistent diameters

- Surface finish is a priority

- Volume production is required

Use CNC Milling If:

- The part has multiple planes or angles

- Detail, contour, or 3D machining is needed

- The design includes pockets or cavities

- The part requires complex customization

Combining both processes may be ideal for multi-feature components.

Where Precision Meets Performance: A Smarter Future Ahead

As industries continue to push the boundaries of design, both CNC turning and CNC milling will remain at the heart of modern manufacturing. The ability to produce accurate, reliable, and application-ready components ensures they remain indispensable across aerospace, medical devices, automotive systems, robotics, and energy infrastructure.

Reliable builders, take Gemsons, for example, mix years of expertise with advanced tools while focusing on accurate results that fit shifting industry demands. Because they handle both precision-turned and milled components in-house, businesses can move faster without challenges.

Strengthening Your Manufacturing Outcomes With the Right Expertise

When it comes to intricate milled pieces or precision turned components, picking an experienced manufacturer makes all the difference in how well your project turns out. Instead of guessing, go with someone skilled in CNC turning and prototype work; alongside precise milling, this combo brings reliable results. They don’t just deliver parts; expect solid advice, steady output, and top-tier accuracy from start to finish.

Businesses wanting more exposure, aiming to grab fresh customers, or showing off niche skills—like CNC machining, precision turning, or milling work—can use sites such as Gemsons; they bring real interest from buyers while boosting presence online by linking skilled providers directly with the right sectors.

Recent Comments