Table Of Content

- CNC Valve Body

- Actuation Mechanism

- Sealing Technology

- Flow Control Features

- Pressure Rating

- Customization Options

At Gemsons, we take pride in our commitment to engineering excellence. Our CNC valves, meticulously crafted with precision, set industry standards for quality and performance. In this comprehensive article, we will delve into the intricate components of our CNC valves, showcasing the unmatched craftsmanship that sets us apart in the industry.

Our CNC valves are essential components used in a wide range of industrial applications, from controlling gas flow in manufacturing processes to ensuring the safety of gas delivery systems. These valves are meticulously designed and crafted to meet the highest industry standards, making them a preferred choice for businesses worldwide.

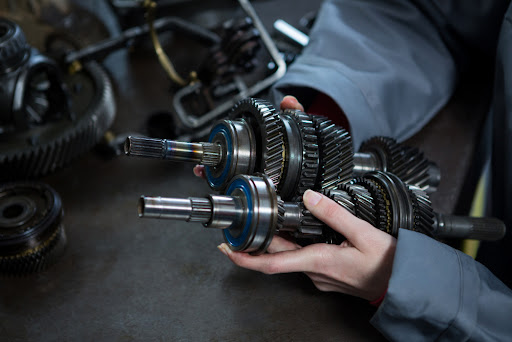

1. CNC Valve Body

The heart of our CNC valves is the meticulously engineered valve body. Crafted from high-quality materials, such as stainless steel or brass, our CNC valve bodies are designed to withstand extreme conditions and ensure longevity. The precision CNC machining process guarantees tight tolerances, resulting in a leak-free performance that exceeds industry expectations.

2. Actuation Mechanism

Efficiency and reliability are at the core of our CNC valves. The actuation mechanism is a critical component responsible for opening and closing the valve. Our CNC valves feature various actuation options, including manual handwheels, pneumatic actuators, and electric motors, allowing customers to choose the best fit for their specific needs.

3. Sealing Technology

To ensure a secure and leak-free operation, our CNC valves are equipped with advanced sealing technologies. Whether it’s a high-pressure gas application or a corrosive environment, our sealing solutions provide unmatched performance. We offer a range of sealing materials, including Viton, Teflon, and metal seals, tailored to the requirements of each CNC valve.

4. Flow Control Features

Precise control over gas flow is essential in many industrial processes. Our CNC valves come with a variety of flow control features, such as throttling plugs, precision orifices, and modulating actuators. These features enable users to fine-tune gas flow rates with exceptional accuracy, ensuring optimal performance of CNC valves in various applications.

5. Pressure Rating

Safety is paramount when dealing with gases under high pressure. Gemsons’ CNC valves are designed to meet and exceed stringent safety standards. Our valves are available in various pressure ratings, ensuring compatibility with a wide range of applications, from low-pressure systems to high-pressure industrial processes.

6. Customization Options

We understand that each application is unique. Therefore, we offer extensive customization options for our CNC valves. Whether it’s adapting the valve to specific dimensions, materials, or actuation methods, our team of experts is dedicated to delivering tailored CNC valve solutions that precisely meet your requirements.

Conclusion

In conclusion, Gemsons’ CNC valves are the epitome of precision engineering and quality craftsmanship. With a focus on durability, reliability, and performance, our valves are trusted by industries worldwide.

If you are looking for a dependable solution for your gas control needs, look no further than Gemsons’ CNC valves. Contact us today to discuss your specific requirements, and our team will be delighted to assist you in finding the perfect CNC valve solution for your application.

Related Topics

Understanding the Basics of CNC Valves and Their Benefits

Explore The Important Tips to Purchase Spare Parts For Your Business

Recent Comments