Table Of Content

- Classification of CNC Turned Components

- Inspection Facilities

- Raw Material Selection

- Threading Options

- Component Size

- Finish

- Supply Chain and Quality Assurance:

- Export Capabilities

- Conclusion

- Frequently Asked Questions

Gemsons Precision Engineering Pvt Ltd is one of the leading CNC turned components manufacturers in India. With a strong focus on precision and quality, Gemsons has established itself as a trusted name in the industry. This blog post aims to provide you with comprehensive information about CNC turned components, Gemsons’ manufacturing capabilities, inspection facilities, raw materials used, threading options, component sizes, and finishing techniques. Whether you are an engineer, a buyer, or an industry professional, this article will serve as a valuable resource for understanding CNC turned components manufacturing in India.

Classification of CNC Turned Components

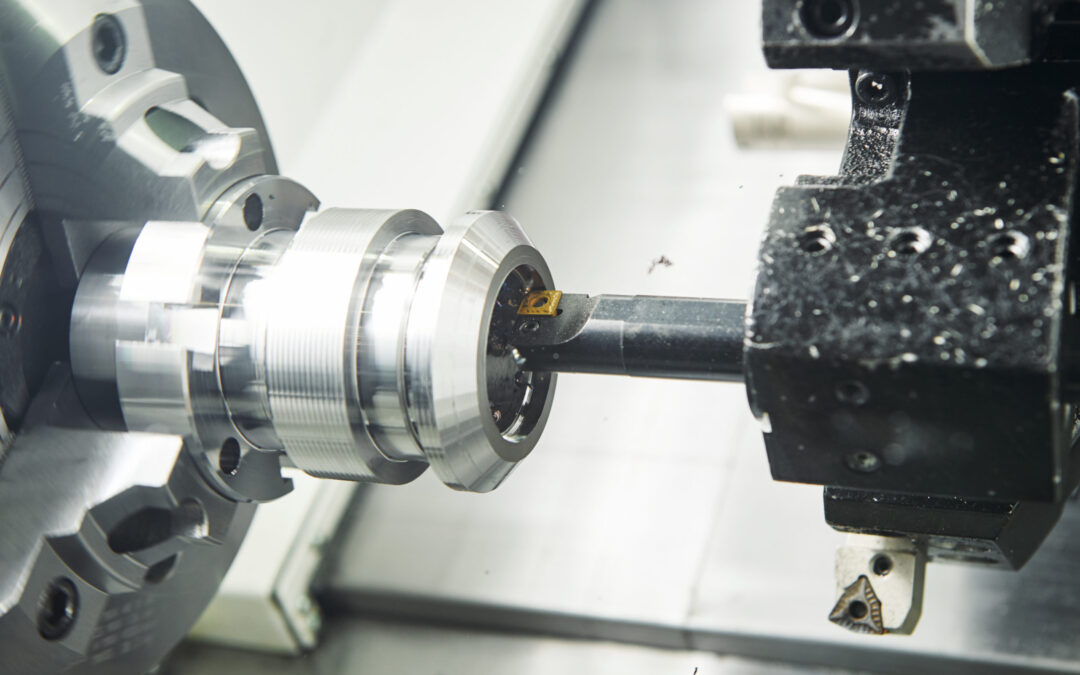

CNC turned components are widely used in various industries due to their precision and versatility. Gemsons Precision Engineering Pvt Ltd specializes in manufacturing a wide range of CNC turned components. These components can be classified into different categories based on their design, function, and application.

- Mechanical Components: Gemsons produces mechanical CNC turned components such as shafts, gears, pulleys, and couplings. These components are vital for transmitting motion, power, and torque within machines and equipment.

- Electrical Components: Gemsons manufactures electrical CNC turned components like connectors, terminals, pins, and sockets. These components play a crucial role in the electrical and electronics industry, ensuring efficient and reliable connectivity.

- Automotive Components: Gemsons provides precision-engineered CNC turned components for the automotive sector, including valves, pistons, bushings, and connectors. These components ensure optimal performance and durability in vehicles.

Inspection Facilities

Gemsons Precision Engineering Pvt Ltd understands the importance of quality control in CNC turned component manufacturing. They have well-equipped inspection facilities to ensure that the components meet the highest standards of precision and accuracy. Gemsons employs various inspection techniques, including:

- Coordinate Measuring Machine (CMM): CMM is used to measure the dimensions and geometric features of CNC turned components accurately. It provides precise 3D measurements, ensuring adherence to specifications.

- Optical Inspection: Gemsons utilizes advanced optical inspection tools to examine the surface quality and finish of the components. This process helps identify any defects, scratches, or imperfections.

- Statistical Process Control (SPC): SPC is employed to monitor and control the manufacturing process in real time. It helps identify any deviations from the desired specifications and ensures consistent quality throughout production.

Raw Material Selection

Gemsons Precision Engineering Pvt Ltd understands that the choice of raw materials significantly impacts the quality and performance of CNC turned components. They source high-quality materials from trusted suppliers to ensure the reliability and durability of their products. Gemsons works with materials such as:

- Stainless Steel: Stainless steel offers excellent corrosion resistance, making it suitable for components exposed to moisture or harsh environments.

- Brass: Brass is known for its high electrical conductivity and good machinability. It is often used in electrical and electronic application

- Aluminum: Aluminum is lightweight, has good thermal conductivity, and is widely used in the automotive and aospace.

- Copper: Copper is valued for its excellent electrical conductivity and thermal properties. It finds applications in electrical connectors and conductive components.

Threading Options

Gemsons Precision Engineering Pvt Ltd offers a range of threading options for CNC turned components. These threading options ensure proper assembly and functionality of the components in various applications. Some common threading options include:

- Internal Threads: Gemsons can produce internal threads of different sizes and types, such as metric, UNC, UNF, and BSP. These threads allow components to be securely fastened to mating parts.

- External Threads: Gemsons can create external threads on components, allowing them to be screwed into other components or fixtures.

- Acme Threads: Acme threads are widely used in applications requiring high load-carrying capacity and efficient power transmission. Gemsons can produce precise Acme threads as per customer requirements.

Component Size

Gemsons Precision Engineering Pvt Ltd can manufacture CNC turned components in various sizes, ranging from small intricate parts to larger components. The size of the components depends on customer specifications and application requirements. Gemsons employs advanced CNC turning machines with multi-axis capabilities to produce components with high precision and accuracy.

Finish

Gemsons understands that the visual appearance and surface finish of CNC turned components are essential for both aesthetic appeal and functional performance. They offer a variety of finishes, including:

- Polished Finish: Gemsons can provide a polished finish to the components, enhancing their visual appeal and smoothness.

- Anodized Finish: Anodizing is a process that creates a protective oxide layer on the surface of aluminum components. It improves corrosion resistance and provides a decorative finish.

- Powder Coating: Powder coating is used to provide a durable and protective finish to components. It offers excellent resistance to chipping, scratching, and fading.

Supply Chain and Quality Assurance:

Gemsons Precision Engineering Pvt Ltd maintains a robust supply chain to ensure a seamless manufacturing process and timely delivery of CNC turned components. They work closely with trusted suppliers to source high-quality raw materials and components. Gemsons follows strict quality assurance procedures at every stage of production, from material inspection to final product testing. Their quality control team conducts thorough inspections to ensure that each CNC turned component meets the required specifications and standards. Gemsons also emphasizes continuous improvement and invests in advanced manufacturing technologies to enhance their production efficiency and quality control processes.

Export Capabilities

Gemsons Precision Engineering Pvt Ltd has expanded its reach beyond India and caters to international clients as well. With a strong commitment to quality, they have successfully built a reputation for exporting precision-engineered CNC turned components to various countries. Gemsons adheres to international standards and regulations to meet the specific requirements of its global customers. They prioritize effective communication, timely delivery, and customer satisfaction to establish long-term partnerships with international clients.

Conclusion

Gemsons Precision Engineering Pvt Ltd is a prominent name among CNC turned component manufacturers in India. With their expertise in precision manufacturing, strict quality control measures, diverse product offerings, and commitment to customer satisfaction, Gemsons has earned the trust of clients across various industries. Whether you require mechanical components, electrical components, or automotive components, Gemsons can deliver high-quality CNC turned components that meet your specific requirements. Their advanced machinery, skilled workforce, inspection facilities, and focus on continuous improvement make them a reliable partner for all your CNC turned component needs. Trust Gemsons Precision Engineering Pvt Ltd for precision, reliability, and excellence in CNC turned components manufacturing in India and beyond.

Frequently Asked Questions

Can Gemsons manufacture CNC turned components with tight tolerances?

Absolutely. Gemsons specializes in manufacturing CNC turned components with high precision and tight tolerances. They employ advanced CNC turning machines and inspection techniques to ensure adherence to specifications.

What is the typical turnaround time for CNC turned components manufacturing?

The turnaround time depends on the complexity of the components and the order quantity. Gemsons strives to provide quick turnaround times while maintaining the highest quality standards. They work closely with customers to determine realistic delivery schedules.

Does Gemsons offer customization options for CNC turned components?

Yes, Gemsons understands that different industries and applications may have unique requirements. They offer customization options for CNC turned components, including material selection, threading options, size variations, and finishes.

Recent Comments